Choosing the right consistency of grease for an application is critical, as a grease that is too soft may migrate away from the area that needs to be lubricated, while a grease that is too stiff may not effectively migrate into the areas that need to be lubricated.

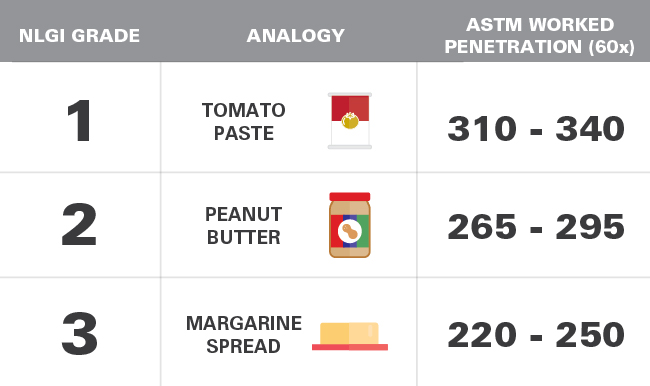

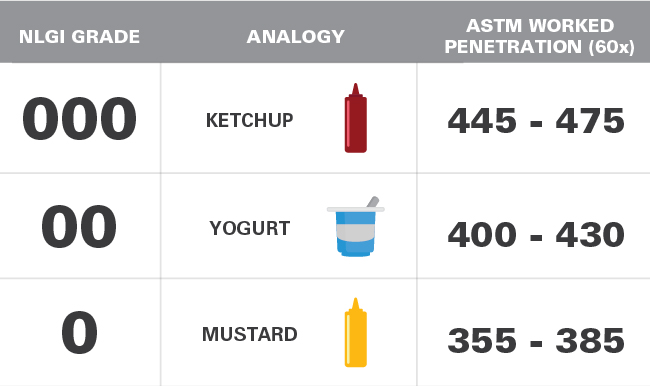

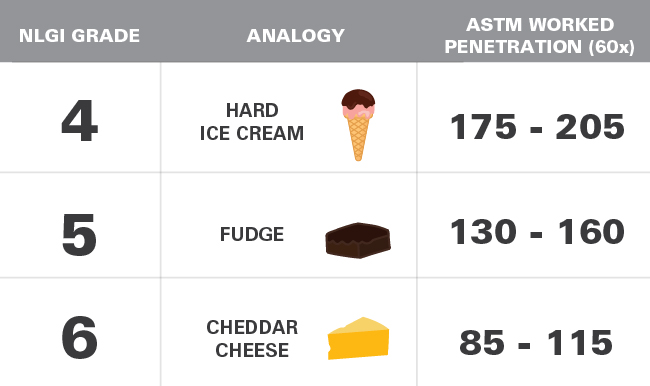

Traditionally, a grease’s stiffness is indicated by its penetration value and is evaluated using the standardized National Lubricating Grease Institute (NLGI) grade chart. The NLGI number is a measure of the grease’s consistency as indicated by its worked penetration value.

The penetration test measures how deep a standard cone falls into a grease sample in the tenths of millimeters. Each NLGI grade corresponds to a specific worked penetration value range. Higher penetration values, such as those over 355, indicate a lower NLGI grade number. The NLGI scale ranges from 000 (semi-fluid) to 6 (solid block like a cheddar cheese spread).

The base oil viscosity and the amount of thickener greatly influence the NLGI grade of the finished lubricating grease. The thickeners in grease function like a sponge, releasing the lubricating fluid (base oil and additives) when force is applied.

The higher the consistency, the more resistant the grease is to releasing lubricating fluid under force. A grease with a low consistency will release lubricating fluid more readily. The right grease consistency is important for ensuring that the appropriate amount of lubricating fluid is provided and maintained in the system for proper lubrication.

![]()

NLGI Grades 000-0

Greases that fall under these grades are categorized into the fluid to semi-fluid range and tend to be less viscous than others. These grades of grease can be beneficial in enclosed and centralized applications, where grease migration is not an issue. For example, a gear box requires a grease within this NLGI range to continuously replenish the lubricant into the contact zone.![]()

NLGI Grades 1-3

A grease with an NLGI grade of 1 has a consistency like tomato paste, where a grease with an NLGI grade of 3 has a consistency more like butter. The most commonly used greases, such as those used in automotive bearings, would use a lubricant that is NLGI grade 2, which has the stiffness of peanut butter. Grades within this range can operate in a higher temperature range and at higher speeds than NLGI grades 000-0. Greases for bearings are typically NLGI grade 1,2, or 3.![]()

NLGI Grades 4-6

NLGI grades categorized in the 4-6 range have a consistency like ice cream, fudge or cheddar cheese. For devices moving at high speeds (greater than 15,000 rotations per minute) an NLGI grade 4 grease should be considered. These devices experience more friction and heat build- up, therefore a stiffer, channeling grease is needed. Channeling greases are more easily pushed away from the element as it rotates, thus leading to less churning and less temperature gain. For example, Nye’s Rheolube 374C is an NLGI grade 4 grease used in high speed bearing applications with a wide temperature range of -40°C to 150°C. Greases with an NLGI Grade of 5 or 6 are not typically used in applications.

Post time: Dec-30-2020